Time to rewrite your playbook for how simulation works. Access all the support you need for design, manufacturing, data management, and professional training in 1 ecosystem.

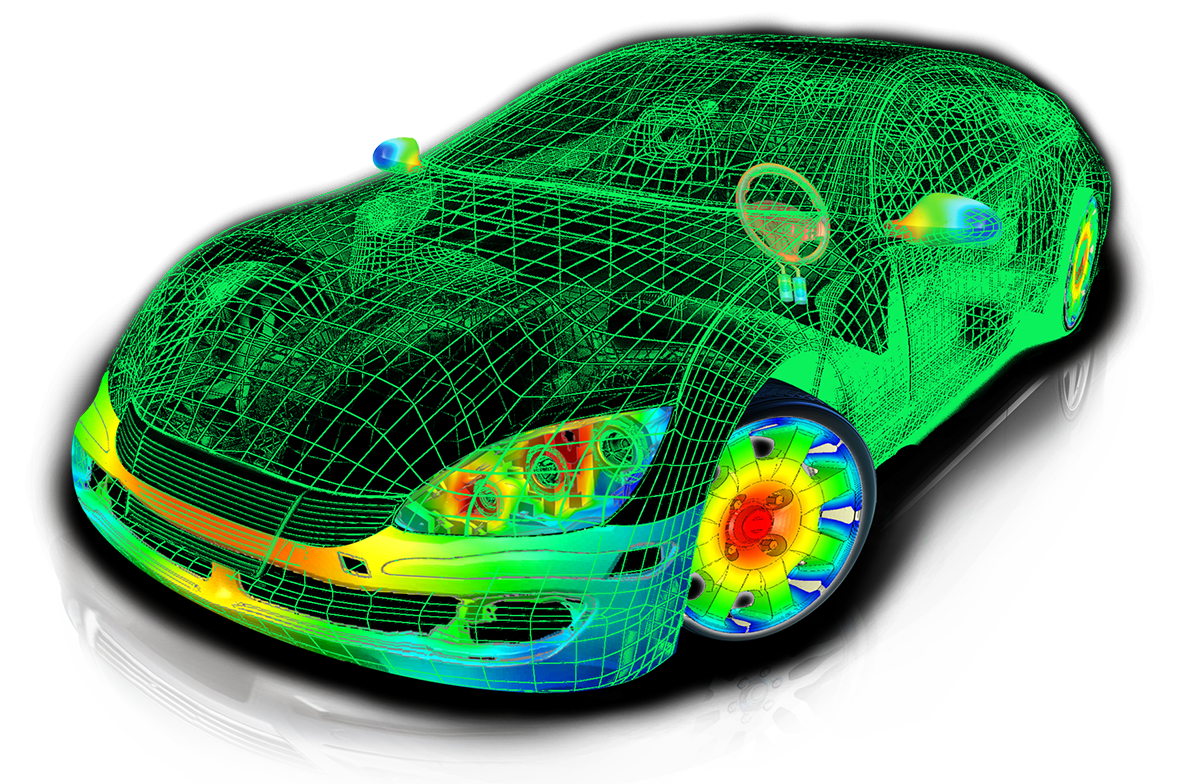

Bring Your Design to Life

Smart Manufacturing

Moldex3D 2022 continues to make great leaps in molding simulation accuracy and simulation capabilities. Digital twin technology is also integrated into the system to capture variables in the actual environment, helping industry achieve digital transformation, maximize manufacturing efficiency, and reduce trial time and costs.

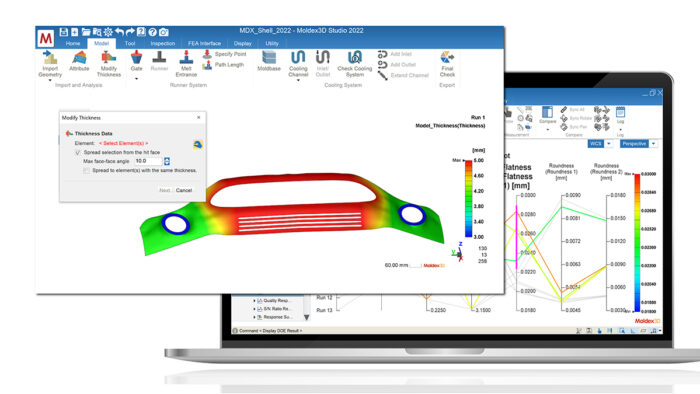

Moldex3D Studio

Create Your Customized Reports

Generate customized molding simulation reports and highlight important molding results based on project needs, which facilitates company standardization and improves team communication.

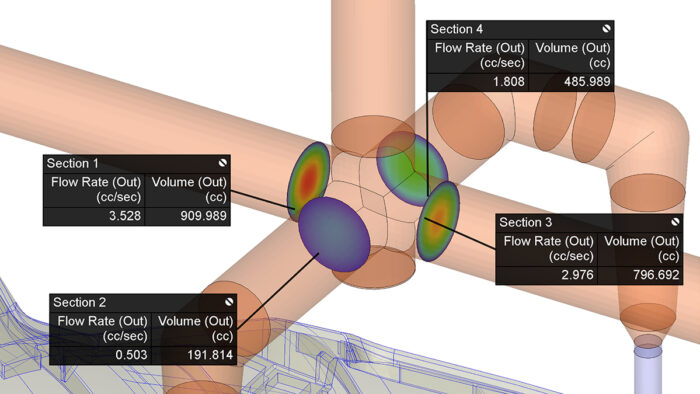

Advanced Measurement Tools

Acquire timely physical information of points and planes with newly added probe and cross-section measurement tools, which allows you to track core problems even on complicated product designs.

Save Calculation Time

Identify influential design factors with Design of Experiment (DOE) Wizard and optimize product quality. DOE and Shell analysis are now supported on Linux, further reducing simulation calculation time and product development process.

New API Feature

Moldex3D Studio API transforms your work routine into an automatic process. It helps you set up simulation, compare simulation results, and optimize processes, saving you precious time to focus on more important tasks.

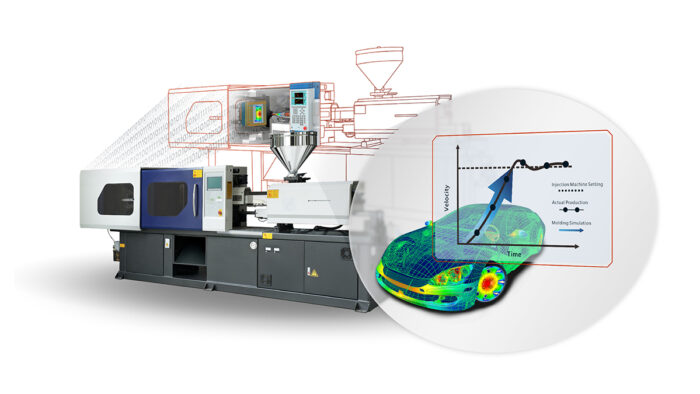

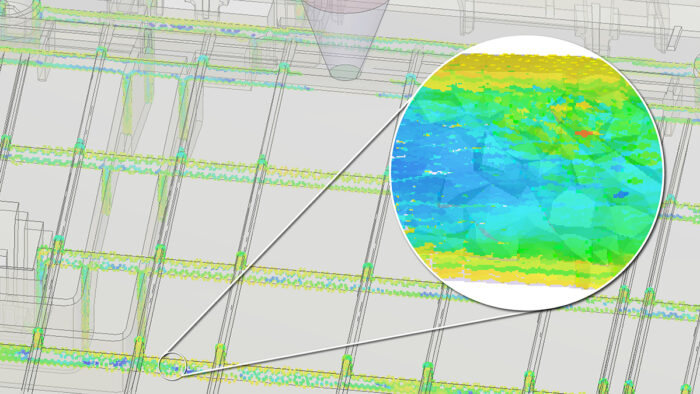

Higher Accuracy in Digital Twin

Machine Characterization

To ensure simulation results reflect the actual manufacturing environment, we build machine digital twins with machine performance and dynamic response and apply these data into CAE analysis, successfully reducing the gap between simulation and reality.

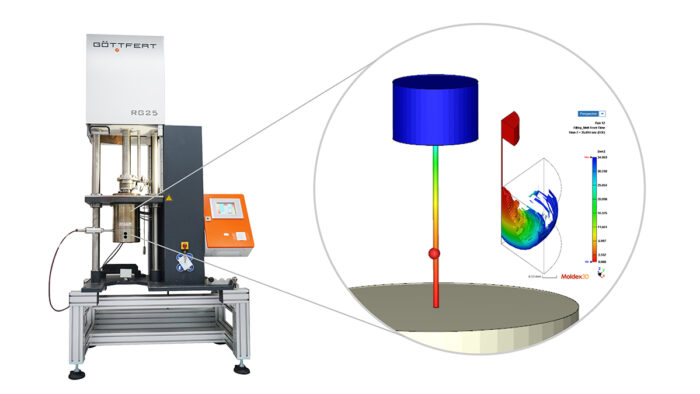

Material Characterization

Moldex3D has established a professional material measurement center with ISO/IEC 17025 certification. It has decades of plastic data measurement technology and experiences to construct complete material digital twins, improving prediction accuracy on injection pressure, warpage, and shrinkage.

4 Major Upgrades in Simulation Capabilities

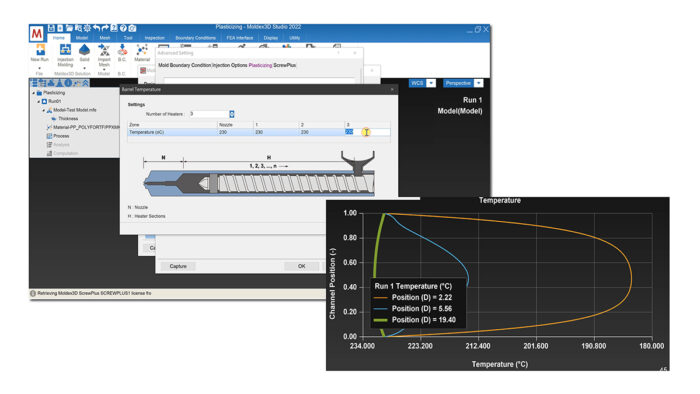

Know What is Going on inside the Barrel

Simulate barrel temperature and pressure changes with plastification analysis, which considers barrel geometry to find optimal parameter setting and geometric structure design.

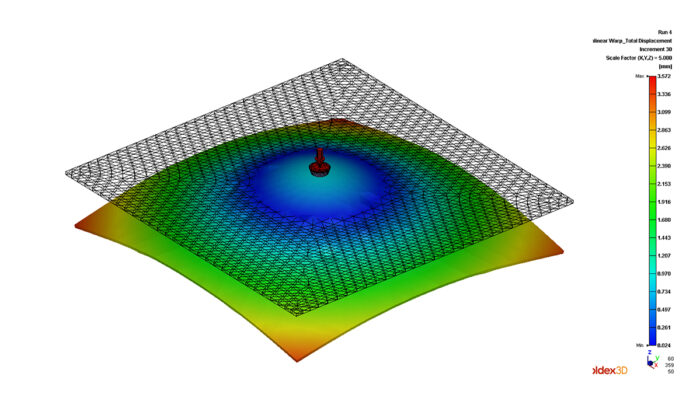

Advanced Warpage Analysis

The newly added large deformation function helps you identify any potential large deformation on products, eliminating possible defects before manufacturing.

Fiber-Orientation Simulation

In response to the increasing lightweight demand caused by environmental awareness, such as carbon reduction and green energy, we develop fiber prediction functions for GAIM, WAIM, and co-injection molding to predict fiber orientation more accurately.

Composite Material Molding

With Moldex3D Studio fully supporting Wet RTM/SMC process analysis, you can see design variables and compare results between different molding processes to optimize product design more intuitively.

Smart Design

Imagine having every product detail ready for mass production at the design stage. Moldex3D makes it happen by providing more than 8,000 plastic material data and machine characteristics, helping you find the best design solution and run accurate simulations with data captured in real world.

Moldex3D SYNC

Smart Design Tools

By performing Design Parameter Study (DPS) on critical dimensions, you can significantly reduce simulation calculation time and identify possible defects in molding.

Automated Design Analysis

sDFM (simulation Design for Manufacturing) report helps you quickly identify key design factors, reduce product development time, and improve team communication efficiency.

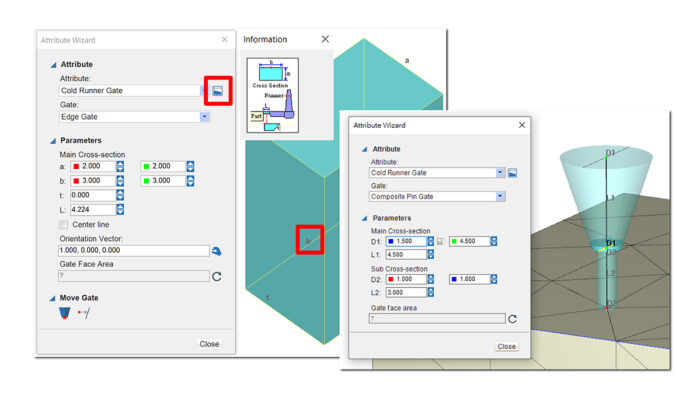

A Full Upgrade on Channel Wizards

Runner/Cooling Channel Wizard

The most commonly used runner gates and cooling channel wizards are optimized to speed up the design process. More diverse layout forms are also provided for different purposes.

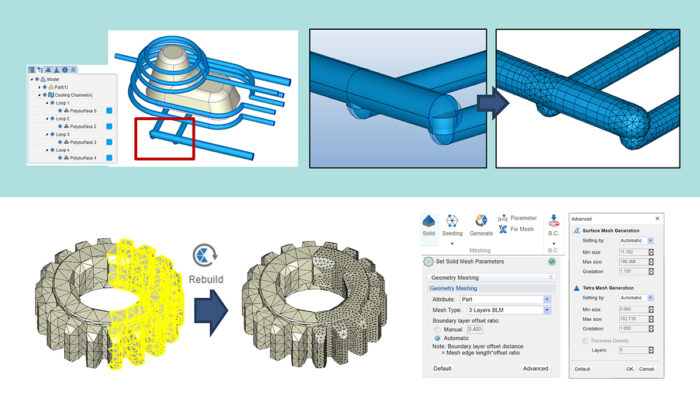

Push for Better Mesh Quality

Preprocessing CAD import and mesh functions are elevated. Now with geometry healing function, you can repair geometric defects, improve mesh quality easier.

Advanced Process Modeling

Multiple Process Modeling Capabilities

A more complete IC Auto Mesh function is established, users can freely create advanced packaging such as CoWoS and InFO types.

Compression Molding Modeling

Compression molding modeling ensures smoother and flexible mesh generation. It significantly increases the automatic generation rate of grids with undercut structures, which makes the product design process more convenient.

Smart Management

Every mold tryout is a precious digital asset for enterprises. iSLM and Material Hub Cloud (MHC) assist enterprises in managing intellectual resources and extract valuable information from pools of data.

iSLM

Moldex3D iSLM records the entire development process of design and mold trial and updates the data on cloud system. Through the data visualization, the entire development process can be seen at a glance, making team work more efficient.

Material Hub Cloud (MHC)

With more than 8,000 material data, you can quickly compare through material physical properties and find your best option. The unique Material Selection Guidance also helps designers and molders find their ideal materials faster and reduce project duration.

Smart Learning

Moldex3D makes learning no longer limited by locations and time. From the basic principles of injection molding to the science courses of polymer materials, you can access the courses on your smartphone or tablet and learn at your own pace.

Moldex3D Plastics E-Learning

Moldex3D Plastics E-Learning (MPE) provides professional terminology, knowledge of injection molding machines, and real case studies in the plastic industry. It helps people who are new in the industry to strengthen their practical capabilities and build competitiveness.

今すぐMoldex3D 2022を体験してみる

お探しのソリューションはMoldex3D 2022にあります。お問い合わせフォームにご記入頂けますと、What’s Newの各種ダウンロードやMoldex3D 2022を体験していただけます。

Copyright © 2022 Moldex3D. All rights reserved. | Privacy Policy