Moldex3D partnered with Sumitomo Heavy Industries on integration between virtual CAE simulation and physical injection molding machine, facilitating digitalization and smart manufacturing.

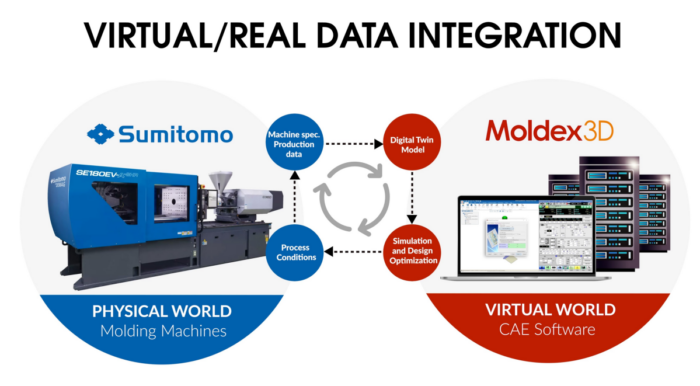

HSINCHU, Taiwan — Dec 1, 2022 — CoreTech System Co., Ltd. (Moldex3D) announced a strategic collaboration with Sumitomo Heavy Industries, Ltd. (SHI) to strengthen the integration between virtual CAE simulation and physical injection molding machines. This partnership set up a two-way bridge that connects the CAE simulation to a real injection molding machine. It not only reduces the gap between design and manufacturing through digital twin technology but also dramatically accelerates time to mass-production.

This collaboration aims to create a virtual representation – “digital twin model” of an SHI injection molding machine in a virtual CAE space by capturing its physical features and machine dynamics and to achieve a more realistic result from Moldex3D simulation. Moreover, the process conditions optimized by simulation will be directly transferred to injection molding machines as an initial set-up of mold tryout through data exchange between Moldex3D software and SHI’s machines. It significantly simplifies the process from mold tooling to mass production.

“Every process engineer knows how time-consuming it is to find optimum process conditions for most of the injection molds. By bidirectional data exchange, our customers can virtually evaluate the most favorable process conditions aimed at their own Sumitomo Heavy Industries, Ltd. injection molding machines before performing the first mold tryout. This cutting-edge technology will significantly speed up time to market.”

Dr. Masaaki Konno, Director of Sales Engineering Department, Plastics Machinery Division, Sumitomo Heavy Industries, Ltd.

“Under the trend of smart manufacturing, digital transformation is an important issue to be faced. With this collaboration, Moldex3D simulation can consider the unique dynamic characteristics of each SHI machine, taking virtual simulation to the next level. It further enhances CAE simulation capabilities and brings CAE simulation results closer to reality.”

Dr. Venny Yang, CEO of CoreTech System, Co., Ltd. (Moldex3D).

In addition, JSOL, Moldex3D’s value-added channel partner in Japan, plays an important role in communication on this cross-country collaboration.

“JSOL has supported SHI for better implementation of CAE software for many years. It is our honor to join this project and facilitate technical communication. We’re excited to promote this new technology to the market.” said Mr. Takahiko Miyachi, Director at JSOL Corporation.

In pursuit of Industry 4.0, this integration established by Moldex3D and SHI, and assisted by JSOL will fulfill the requirements of the injection molding industry and will connect the virtual world and physical environment. The data exchange between CAE simulation and injection molding machine will be more straightforward, and the product development workflow from design to production will be faster and smoother.

About CoreTech System (Moldex3D)

CoreTech System Co., Ltd. (Moldex3D) has been providing the professional CAE analysis solution “Moldex” series for the plastic injection molding industry since 1995, and the current product “Moldex3D” is marketed worldwide. Committed to providing advanced technologies and solutions to meet industrial demands, CoreTech System has extended its sales and service network to provide local, immediate, and professional service. CoreTech System presents innovative technology, which helps customers troubleshoot from product design to development, optimize design patterns, shorten time-to-market, and maximize product return on investment (ROI). More information can be found on Moldex3D Website.

About Sumitomo Heavy Industries (SHI)

The Sumitomo Heavy Industries Group is an all-around machinery manufacturer engaged in the production of general industrial machinery, precision machinery, construction machinery, ships, environmental plant facilities, and other products. Our Power Transmission & Controls Group (PTC) is a business unit that develops and produces variable speed gears and gear reducers. More information can be found on SHI Website.

About JSOL

JSOL Corporation is a leading company of CAE solution provider with cutting edge technology. It provide numerical analysis solution from service to software, data, from micro scale continuum to micro scale of molecular dynamics. The high end technology helps customers through various industries to develop high quality products with less cost and time, and accelerate the digital transformation in engineering design. In January of 2009, following a business and capital alliance with NTT DATA, the company name was changed to JSOL. It has evolved as a member of the NTT DATA Group and SMBC Group to allow an even wider range of needs to be met. More information can be found on JSOL Website.