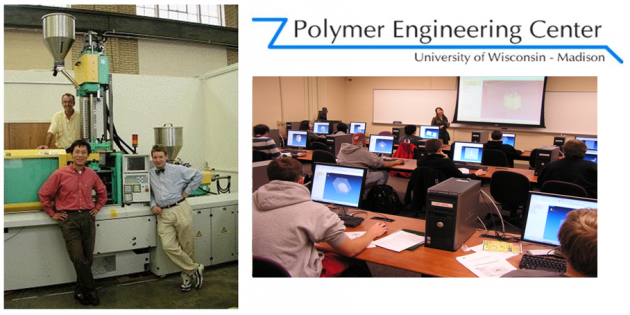

The Polymer Engineering Center(PEC) at the University of Wisconsin(UW), Madison, has been implanting the use of Moldex3D injection molding simulation software since 2006 to support their research and academic projects.

“Moldex3D has been acting as an important role helping us to obtain insightful information about the injection molding process and learn how various processing parameters affect the parts produced. Moldex3D also sheds light on how product and mold design impact product quality,” says Lih-Sheng Turng, professor of the PEC.

Professor Turng uses Moldex3D as an educational tool in his class “ME 419: Fundamentals for Injection Molding”. PEC has been using Moldex3D injection molding simulation software to study the material properties and optimal process condition on the moldability and part quality of injection molded part and mold designs parts.

“We really appreciate that we could have this chance to access Moldex3D injection molding simulation software during the class, which greatly helped us, especially the complete and state-of-the-art modules and 3D mesh analysis solutions certainly had contributed to our academic research and projects,” one of the ME 419 students proudly says.

Professor Turng is recognized for his research into the science and engineering of polymer injection molding. His research has been supported with the use of Moldex3D which encompasses novel processes as well as new materials. He has been working in the area of microcellular injection molding, and has extended his research into nanocomposites, bio-based polymers, and tissue engineering scaffolds.

Moldex3D will continuously support Professor Turng as well as UW PEC’s research with the latest innovation of Moldex3D injection molding simulation software—the simulation technology for the new generation.

About Professor Lih-Sheng Turng

Professor Turng is recognized for his research into the science and engineering of polymer injection molding.

His research encompasses novel processes as well as new materials.

He has been working in the area of microcellular injection molding, and has extended his research into nanocomposites, bio-based polymers, and tissue engineering scaffolds.

Numerous grants and awards supporting his work have resulted, including the National Science Foundation (NSF) Major Research Instrumentation (MRI) Award, NSF Academic Program Awards, and several Wisconsin Innovation & Economic Development Research Program awards. He is the Co-Director of the Polymer Engineering Center and Engineering Polymer Industrial Consortium at UW-Madison, and NSF Industry/University Corporative Research Center (I/UCRC) that supports faculty research and outreach.

Turng had been with C-MOLD, a company recognized for its advanced plastics CAE simulation packages, for 10 years before joining UW-Madison in the summer of 2000. At C-MOLD, Turng was the Principal Investigator for four Small Business Innovation Research (SBIR) Phase I, Phase II projects, and research grants from the National Science Foundation (NSF) and the New York State Science and Technology Foundation.

At present, Professor Turng serves as the Chair and the Board of Directors of the Injection Molding Division of the Society of Plastics Engineers (SPE). In addition, he is on the Editorial Board for the Journal of Advances in Polymer Technology, Journal of Biobased Materials and Bioenergy, Journal of Cellular Plastics, and International Journal of Polymer Materials. Professor Turng was the invited panelist and speaker at the 2003 Wisconsin Economic Summit IV and plenary or keynote speaker at a number of other international conferences